Gatorfoam®

- Description

- Additional information

- RESOURCES

Description

The original high-performance foam board

GATORFOAM has been the display industry’s leading high-performance foam board for more than 30 years. The unique combination of its foam core and wood-fiber veneer facers create an extremely rigid and durable yet light weight solution, perfect for mounting and other interior display applications.

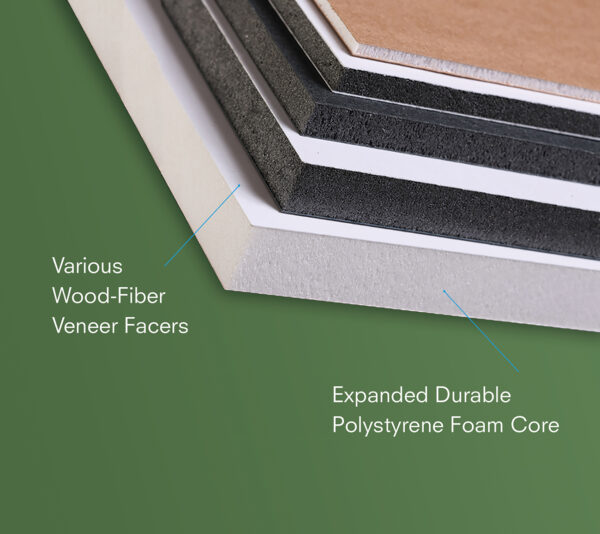

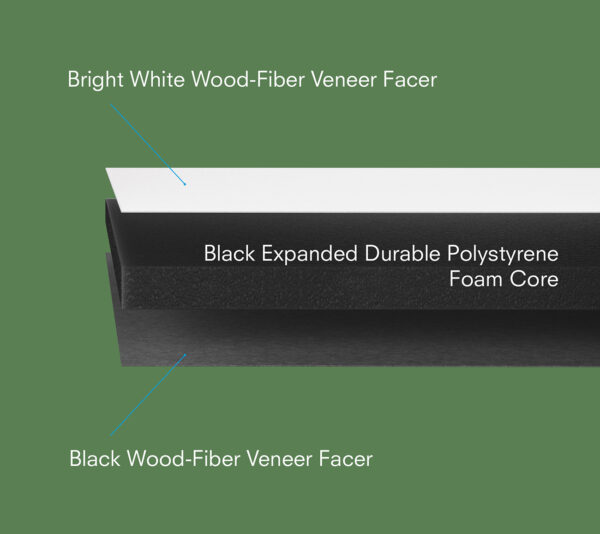

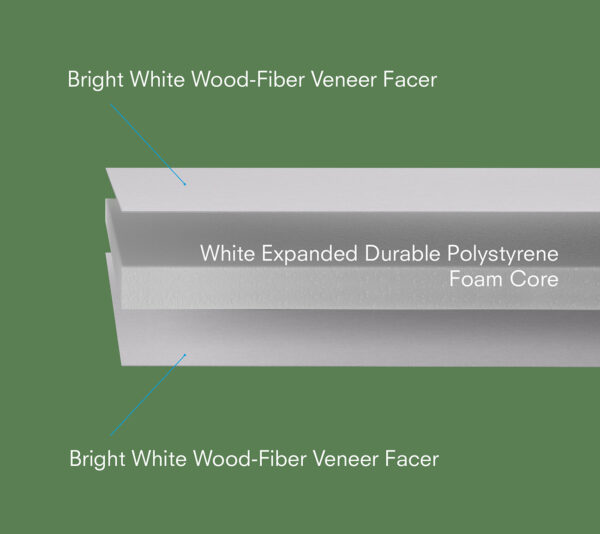

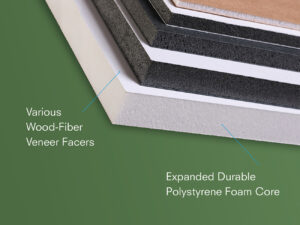

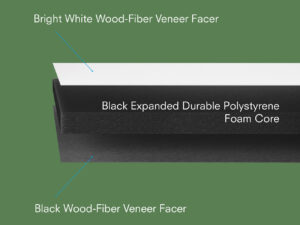

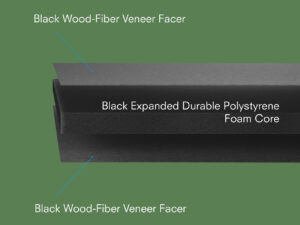

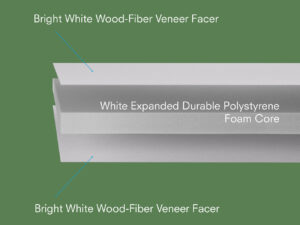

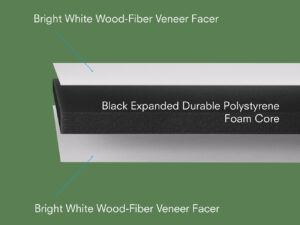

Material Composition

GATORFOAM is comprised of extruded polystyrene foam bonded between two layers of wood-fiber veneers. Made in the USA.

Advantages with GATORFOAM®

- The original, completely unique high-performance graphic arts foam board

- Wood-fiber veneers provide extreme rigidity – excellent for mounting applications

- Bright white facer provides very good digital and screen printing results

- Routs and cuts cleanly for easy fabrication

- Excellent dent and scratch resistance

- Lightweight with good dimensional stability

- Available in a wide range of thicknesses and sheets sizes

- Consistent bright white surface and sheet thickness

- Facers are purchased from suppliers that participate in either the Sustainable Forestry Initiative (SFI) or have a Forest Management Certification

Recommended Applications

Below are some of the more common applications for which GATORFOAM® provides a solution. While these are frequent uses for our material, we love to see the unique applications designers & artists come up with!

- POP / POS Displays Medium-term application life

- Exhibits & Kiosks Medium-term application life

- Interior Signage & Displays Medium-term application life

- Framing Long-term application life

- Hanging Signage Medium-term application life

- Window Displays Medium-term application life

- Promotional Campaigns Medium-term application life

- 3-Dimensional Displays Medium-term application life

- Retail Fixtures Medium-term application life

- Dimensional Letters Medium-term application life

Recommended Fabrication Methods

Thanks to over 40 years of manufacturing experience, we are able to provide general fabrication guidelines and best practices that have been successful with our materials.”

- Mounting

- Digital Printing

- Screen Printing

- Painting Do not expose core to solvent-based paints

- Saw Cutting

- Routing

Additional information

| Size | 48" x 96", 60" x 120" |

|---|---|

| Thickness | 1", 1/2", 2", 3/16" |

| Color | Black, White, White/Black/Black, White/Black/White |